UltraTech Cement partnered with KOMPANIONS to modernize its technical training through an Augmented Reality based solution. The training module focused on the cleaning and maintenance procedures for two critical components, the Electrical Grid Resistance Regulator and the Electrical Liquid Resistance Starter.

The solution now serves as a scalable benchmark for AR-driven industrial training.

UltraTech Cement is India’s largest manufacturer of grey cement and a leader in building materials. With multiple plants and high-demand production cycles, their operations rely heavily on the proper maintenance of mission-critical equipment.

Traditional SOP-based training was time-consuming and often prone to human error. New staff found it difficult to grasp the complexity of electrical equipment procedures through static manuals alone.

Critical machinery like the Electrical Grid Resistance Regulator and Liquid Resistance Starter demand precision and strict adherence to protocols. Any lapse could lead to safety incidents or equipment damage.

KOMPANIONS designed an AR experience that overlays real-time, device-specific instructions directly onto the equipment, allowing technicians to follow procedures with confidence and accuracy.

Accessible via mobile devices or AR headsets, the solution allows workers to visualize instructions while keeping both hands free—boosting efficiency, reducing errors, and enabling real-time learning.

Industrial plants like UltraTech are evolving rapidly—and so should training. By introducing AR to complex maintenance workflows, KOMPANIONS helped reduce downtime, boost safety, and support faster knowledge transfer. This model can scale to other plants and maintenance-heavy industries effortlessly.

Looking to modernize industrial training with AR or VR?

Connect with KOMPANIONS today to explore how immersive technology can make your workforce smarter, faster, and safer.

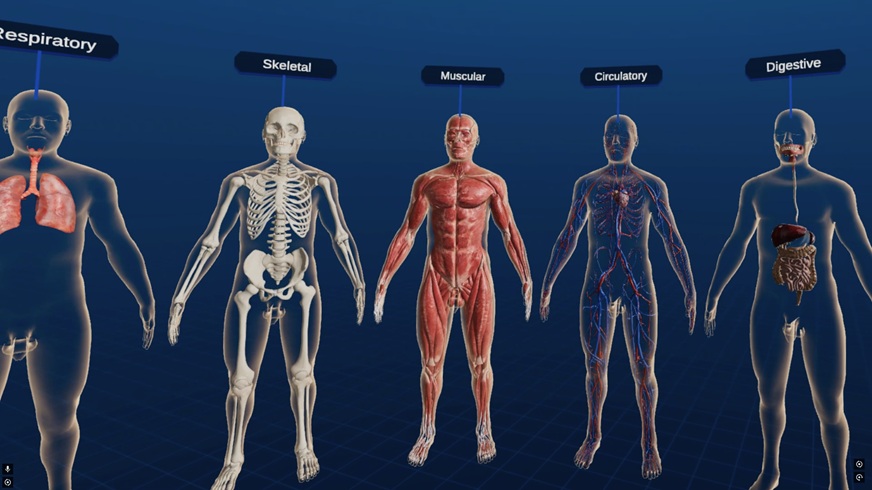

Learn how NIA Jaipur leverages immersive VR modules developed by KOMPANIONS to teach human anatomy and physiology more effectively to students pursuing Ayurveda education.

Learn MORE

Discover how KOMPANIONS used BIM to create a VR walkthrough and construction training simulation for DMRC’s underground metro project—boosting safety awareness, process clarity, and training effectiveness.

Learn MORE

See how KOMPANIONS improved safety and training efficiency at Hindalco with a VR-based Anode Change Process simulation, enabling risk-free learning, quicker onboarding, and measurable performance gains.

Learn MOREReady to take the first step towards unlocking opportunities, realizing goals, and embracing innovation? We're here and eager to connect.