Hindalco Industries, a flagship company of the Aditya Birla Group, partnered with KOMPANIONS to enhance workforce safety and operational efficiency using Virtual Reality (VR). We designed a customized VR simulation for the Anode Change Process—a critical operation in their potline workflow.

The result? A safer, more efficient, and scalable training program that enabled hands-on learning without real-world risk.

Hindalco Industries Limited is one of the world's largest aluminium rolling companies and a global leader in copper. As part of the Aditya Birla Group, Hindalco runs large-scale, high-risk industrial operations requiring strict safety protocols, particularly in processes involving high-temperature and electrically intensive tasks like anode changing.

The Anode Change Process is both complex and hazardous, involving heavy equipment, electrical hazards, and precise sequencing. Traditional training methods were:

Hindalco needed a risk-free yet realistic training method to train new employees and upskill existing workers, without disrupting operations or compromising safety.

We created a high-fidelity Virtual Reality training module focused on the Anode Change Process under Pot Processes. The training simulation allowed workers to:

The Anode Change Process is both complex and hazardous, involving heavy equipment, electrical hazards, and precise sequencing. Traditional training methods were:

This case study reflects a larger shift in how heavy industries are rethinking safety training. By integrating VR-based skill training, companies like Hindalco are minimizing human risk, maximizing knowledge retention, and aligning with future-ready training methodologies. The solution is scalable across plants and applicable to multiple high-risk processes.

Ready to modernize your workforce training?

Talk to our team to explore how KOMPANIONS’ VR safety modules can reduce risk and improve performance at your plant.

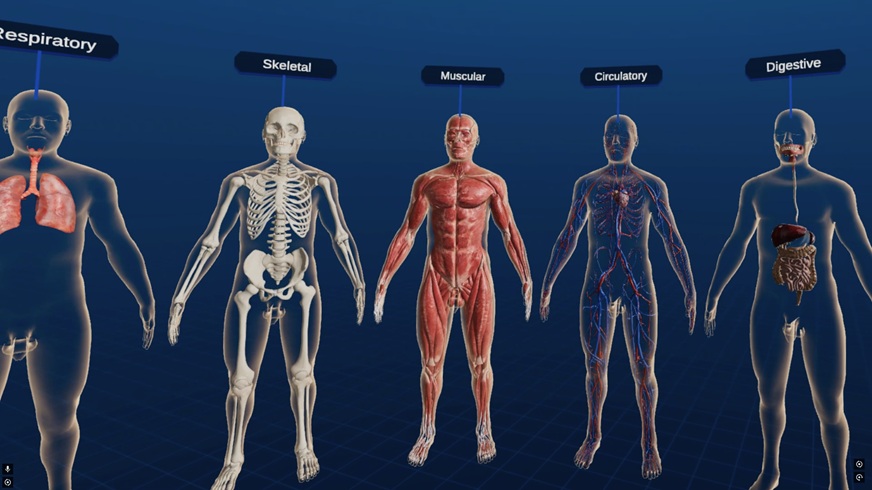

Learn how NIA Jaipur leverages immersive VR modules developed by KOMPANIONS to teach human anatomy and physiology more effectively to students pursuing Ayurveda education.

Learn MORE

Discover how KOMPANIONS developed an AR training solution for UltraTech Cement, enabling step-by-step maintenance of critical electrical equipment and enhancing overall plant efficiency.

Learn MORE

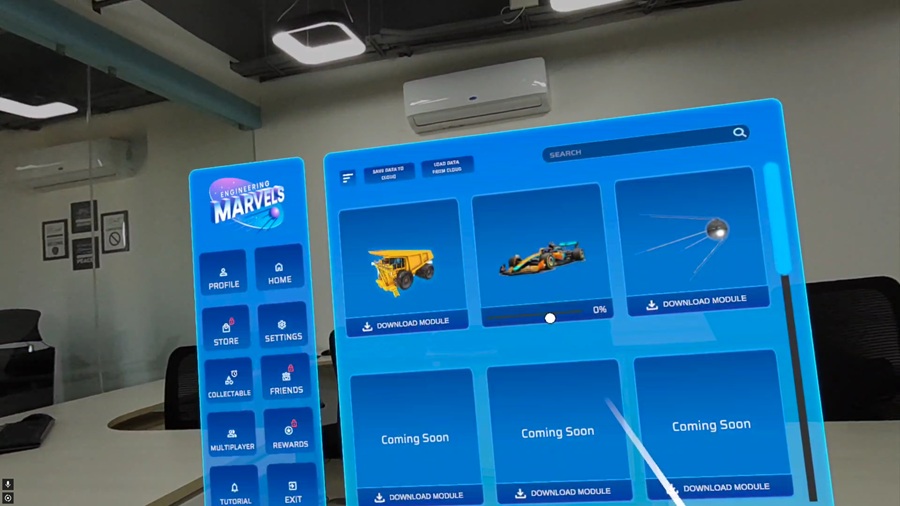

Discover how Meta and KOMPANIONS created Engineering Marvels—a collaborative MR/VR experience that transforms STEM education through hands-on, interactive engineering simulations.

Learn MOREReady to take the first step towards unlocking opportunities, realizing goals, and embracing innovation? We're here and eager to connect.