Article By: Robin Gupta

June 09, 2025 | 5 Minutes Read | Updated On: 11 June 2025

How AR Is Transforming the Factory Floor: Real-World Insights

In recent years, industrial leaders have started seeing the factory floor through a different lens, quite literally. Thanks to AR for factory deployments, the way work gets done is changing from the ground up. Augmented Reality (AR) isn’t just a cool add-on anymore, it’s a practical, results-driven tool being embedded into real production workflows.

So, what’s really happening on factory floors worldwide? Let’s walk through the tangible, real-world impact of AR in manufacturing.

Understanding the Need for AR in Today’s Factories

Manufacturing setups, especially in high-risk and high-volume industries, face several consistent challenges:

- Complex machinery maintenance

- High human error in inspections

- Delays in onboarding new technicians

- Lack of real-time process visibility

- Inefficient collaboration between teams

That’s where AR for factory floor operations enters the picture. With AR-powered headsets or mobile devices, technicians can now overlay real-time information onto machines, equipment, and workspaces, resulting in faster decisions and fewer mistakes.

How AR Is Deployed on the Factory Floor

Here are specific ways AR is currently being used:

1. Remote Assistance for Maintenance

Instead of waiting for a specialist to arrive, factory teams can now wear smart glasses and connect live with remote experts. The expert sees what the technician sees and provides step-by-step guidance. This saves days of downtime.

2. Hands-Free Work Instructions

With AR wearables like smart glasses or HoloLens, factory workers can access visual instructions overlaid directly onto machinery. It means less dependency on printed manuals or guessing the next step.

3. Training New Workers Faster

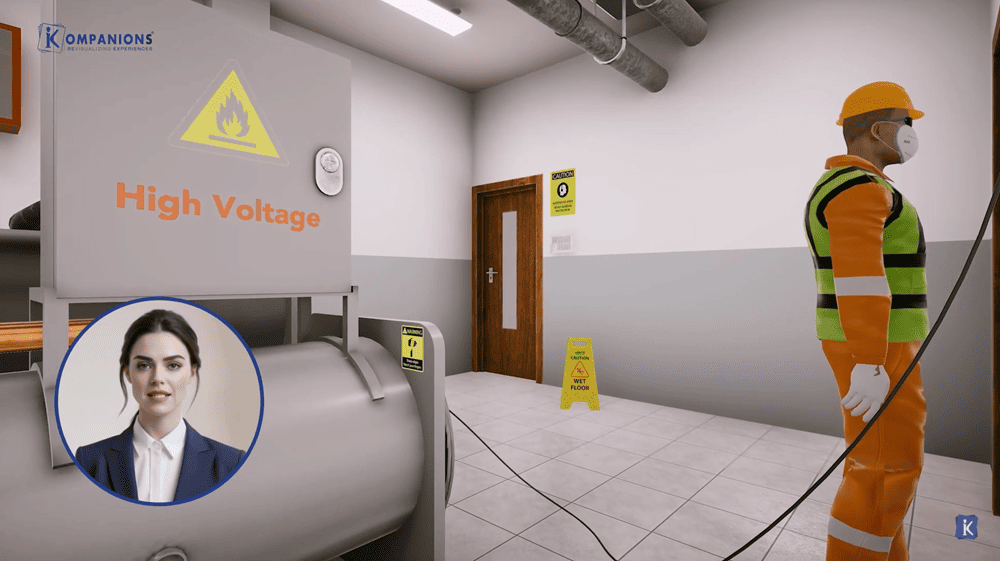

New employees can be onboarded using immersive walkthroughs of factory tasks. They can practice virtually without disrupting operations. AR helps simulate rare but important situations, like system breakdowns, without any actual risk.

4. Error Prevention and Safety Checks

AR-assisted inspections guide workers through every checkpoint, highlight missed steps, and verify completion. It reduces human error and increases compliance with SOPs. This is where VR safety solutions also complement AR setups.

| Use Case | AR Application | Benefit |

|---|---|---|

| Machine Maintenance | Live expert support, 3D exploded views | Quicker fixes, fewer delays |

| Quality Control | Visual overlay of inspection checkpoints | Reduced human error |

| Assembly Operations | Step-by-step guided tasks | Fewer training hours |

| Safety Compliance | AR-based safety walk-throughs | Better adherence to safety protocols |

| Real-time Equipment Status | IoT data visualization over AR | Instant fault detection |

How Kompanions Supports AR for Factory Deployments

At Kompanions, we specialize in industrial AR/VR, metaverse, and XR development tailored for manufacturing. From AR for factory floor walk-throughs to VR-based safety drills, our solutions are built for function, not just form.

We recently partnered with a mid-sized manufacturing unit in Pune to create an AR-based training system for their maintenance team. The result? Downtime dropped by 40% in the first quarter post-deployment.

The Hardware Behind the Magic

Technologies used in factory AR solutions:

- Microsoft HoloLens 2: Commonly used for HoloLens in manufacturing applications. Allows workers to work hands-free while receiving layered digital info.

- Realwear Navigator: Rugged and voice-controlled, perfect for dirty or loud environments.

- AR-Enabled Tablets/Phones: Quick-start tools for SMEs to test AR without large upfront investments.

AR hardware today is designed for tough environments, resistant to dust, drops, and even oil splashes.

Real-World Industry Examples

- Boeing reported a 25% productivity increase using AR instructions for wire harness assembly.

- GE Healthcare implemented AR-assisted inspections and saw a 46% drop in errors.

- Caterpillar uses AR for remote guidance in field repairs, saving thousands in travel costs.

These examples reinforce how AR in manufacturing is more than just a buzzword.

Who Benefits Most?

- Large-Scale Manufacturers: For process automation and worker safety

- SMEs: Looking for affordable, scalable industrial AR/VR for SMEs

- Training Centers: To simulate complex industrial environments for learners

Ready to upgrade your factory floor with AR? Contact Kompanions today and see the impact in real time.

Book a Free DemoThe Role of IoT and XR Together

When AR is integrated with real-time machine data from IoT sensors, the results are transformative:

- Live alerts of machine overheating

- Visual data like temperature or vibration right on the machine itself

- Predictive maintenance notifications before failure

This is where IoT in manufacturing converges with AR to create intelligent factories.

Things to Consider Before Implementing AR

- Start Small: Begin with one workflow or process before scaling.

- Select the Right Hardware: Match devices to your factory environment.

- Train Your Workforce: A good tool still needs human expertise.

- Measure the ROI: Track productivity, error rate, and training time.

"The real innovation isn’t just in what AR can do—it’s in how your people use it."

Final Thoughts

The future of the factory floor is no longer mechanical—it’s intelligent. With tailored deployments of AR for factory workflows, manufacturers can cut down errors, accelerate output, and keep their workforce engaged and safe.

It’s not about replacing people. It’s about empowering them.

If you’re exploring how to future-proof your production line, now’s the time to look beyond traditional automation. Start with small AR deployments, scale intelligently, and use tools that adapt to your environment and people.

Want to see how AR can fit into your factory's future? Get in touch with us at Kompanions and let's get started.