Article By: Robin Gupta

January 31, 2025 | 5 minutes to read | Updated On: 15 May 2025

Revolutionizing Manufacturing with Augmented Reality: Benefits, Use Cases, and Examples

With rapid tech evolution, AR is becoming key in several industries. It has already made a mark in manufacturing and is likely to reach a market of USD100 billion by 2030. (Source: Custom Market Insights (CMI))

The manufacturing process demands accuracy and attention to detail. A small mistake can cause the company to lose money. AR-powered smart glasses can help workers perform tasks better, reduce errors, and improve quality control.

VR and AR solutions aren't widely used yet, and business leaders may not know how these technologies can benefit manufacturing operations. This guide provides benefits, use cases, and examples of AR in manufacturing.

What is AR in Manufacturing?

Augmented Reality in manufacturing blends digital information with real-world environments to enhance production, training, maintenance, and quality control. It gives step-by-step guidance, reduces mistakes, improves workplace safety, and makes production faster and more efficient. Using smart glasses, tablets, or AR headsets, manufacturers can overlay critical instructions, 3D models, or sensor data directly onto machinery or workspaces.

As industries move toward smarter factories, AR becomes a key tool for streamlining operations, ensuring faster onboarding, and enabling real-time collaboration across teams.

Benefits of Augmented Reality in Manufacturing

Several manufacturers and industries are implementing augmented reality. It improves efficiency by quickly reducing downtime, finding problems, and keeping processes moving.Here are some key benefits of AR in industrial and manufacturing settings:

1. AR enhances productivity with real-time guidance

Augmented Reality empowers manufacturing workers with real-time, hands-free instructions directly in their field of vision. By minimizing the need to constantly refer to manuals or supervisors, AR accelerates task completion, improves accuracy, and shortens overall cycle times.

This technology significantly boosts shop floor productivity while also helping reduce machinery downtime and operational costs. Learn more about how AR-powered interactive user manuals are revolutionizing the way we approach product understanding and maintenance.

3. Simplified manufacturing processes through AR

Complex manufacturing tasks become simpler and more intuitive with AR-powered visual workflows. Step-by-step digital instructions and predictive troubleshooting help workers complete intricate assembly tasks faster and with fewer errors.

By minimizing rework and delays, AR-driven process optimization leads to higher operational efficiency and smoother production lines.

3. Better product development

Image source: BMW Group

Image source: BMW Group

AR transforms product development by enabling virtual prototyping, remote collaboration, and real-time design validation. Manufacturers can save substantial costs by minimizing physical prototypes, reducing travel expenses for expert reviews, and avoiding on-site visit fees.

Early-stage design adjustments and predictive maintenance further help prevent expensive downtime, resulting in faster time-to-market for new products.

4. AR Increase worker engagement & retention

The immersive, interactive experience offered by Augmented Reality makes training and task execution more engaging for workers. 3D visualizations, virtual simulations, and real-time feedback keep employees motivated and invested in their work.

Enhanced engagement not only improves task performance but also strengthens worker retention in a competitive manufacturing labor market.

5. Augmented reality streamlines warehouse management

AR can save time by managing inventory, guiding product picking, and cutting downtime. It can also help technicians diagnose and fix problems and enhance employee training.

AR can save time by managing inventory, guiding product picking, and cutting downtime. It can also help technicians diagnose and fix problems and enhance employee training.

By overlaying digital pick lists and navigation cues, AR can guide employees to locate, retrieve, and manage inventory faster and more accurately. It also enables real-time equipment diagnostics, reducing downtime, improving asset management, and enhancing employee training for warehouse operations.

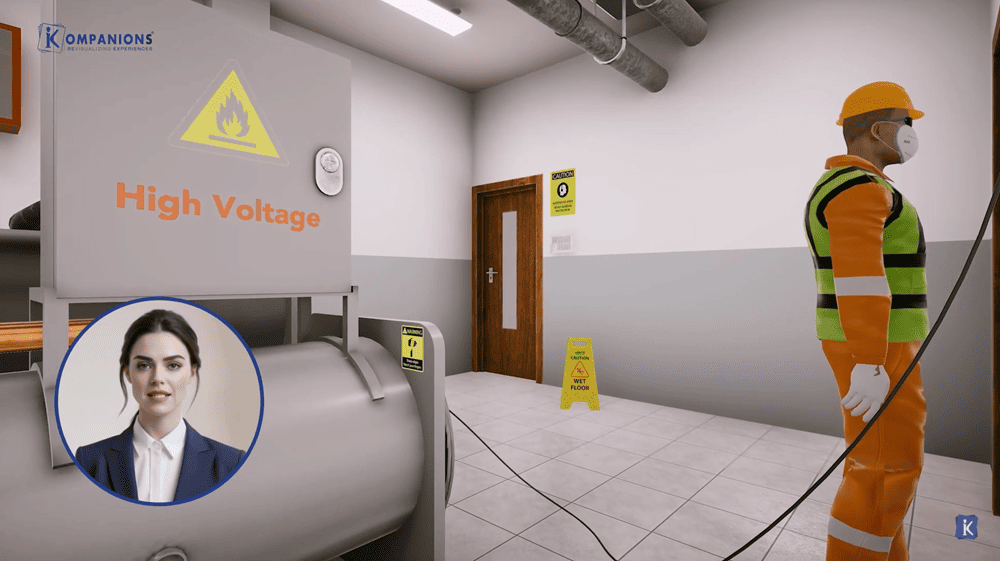

6. AI manufacturing training reduces risk and improves workplace safety

AR doesn't just replace real equipment and people. It also creates a safe, experiential learning environment. It lets workers practice tasks virtually, without risk, improving worker safety, inspection, training, and workflow.

By simulating real-world scenarios, AR reduces on-the-job accidents, minimizes training risks, and improves worker readiness. This proactive approach enhances operational safety, streamlines inspections, and supports regulatory compliance.

Which Benefit of AR in Manufacturing Matters Most to You?

Use Cases of Augmented Reality in Manufacturing

Augmented reality is transforming manufacturing by improving efficiency, precision, and training. From assembly assistance to quality control, AR streamlines operations and enhances worker productivity across various stages of production.

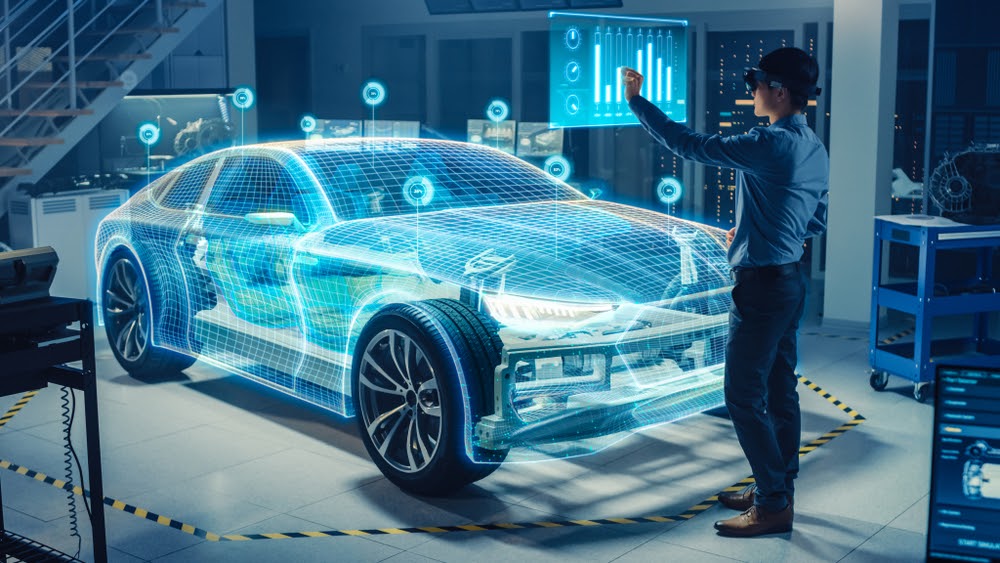

1. AR in Car Manufacturing

The car industry is using augmented reality (AR) for design, assembly, and maintenance. Augmented Reality is revolutionizing automotive manufacturing by enhancing precision, reducing errors, and speeding up complex assembly tasks.

According to PwC, AR can reduce assembly time by up to 25%. Major players like BMW use AR to visualize complex engine assemblies, improving accuracy and training new technicians faster. Ford implemented AR in their design validation process, which helped them shorten vehicle development cycles by 8–10 months, leading to faster innovation and significant cost savings.

2. Augmented Reality Factory Applications

AR factory setups enable real-time monitoring of production lines, allowing workers and managers to visualize machine performance, detect issues early, and optimize workflows.

This ensures smooth manufacturing operations, reduces downtime through predictive maintenance, and enhances worker safety by providing hands-free, on-the-spot guidance and troubleshooting.

3. Digital Twins and BIM for Manufacturing and Construction

Using BIM and digital twins for construction, companies create highly detailed virtual replicas of machines, equipment, and infrastructure.

These digital models enable real-time performance monitoring, streamline design processes, and support predictive maintenance, reducing costs and minimizing risks associated with operational inefficiencies and unexpected failures.

Additionally, integrating VR in construction allows stakeholders to immerse themselves in these virtual environments, enhancing project visualization, improving design accuracy, and facilitating better decision-making through interactive simulations and virtual walkthroughs.

4. Augmented Reality in Pharma Manufacturing

AR in pharma manufacturing is enhancing drug formulation, precise tracking, and employee training in controlled environments like cleanrooms.

AR in pharma manufacturing is enhancing drug formulation, precise tracking, and employee training in controlled environments like cleanrooms.

By overlaying digital information onto real-world processes, AR helps maintain compliance, reduce errors, and improve efficiency in highly regulated pharmaceutical production and research facilities.

Real-Life Examples

Some of the real-life experiences from the manufacturing sector using Augmented reality solutions include:

1. Airbus utilizes Microsoft HoloLens 2 AR glasses to guide workers in assembly tasks. These glasses show visual data points and simplify complex assembly tasks with step-by-step instructions.

2. Taqtile's mobile AR solution, Manifest, improves quality inspections. It gives workers step-by-step visual instructions in their field of view, ensuring standardized procedures and reducing errors.

2. Taqtile's mobile AR solution, Manifest, improves quality inspections. It gives workers step-by-step visual instructions in their field of view, ensuring standardized procedures and reducing errors.

The platform lets you report faults in real time. It can automatically capture data and connect you with experts, making it easier to handle and record issues during inspections.

3. Vuforia's AR solutions improve maintenance and repair tasks. They give techs real-time, in-context guidance. Vuforia overlays 3D work instructions onto equipment.

This helps technicians perform complex procedures accurately and efficiently. This method reduces reliance on manuals, speeds up repairs, and improves first-time fix rates.

Unlock the power of AR to streamline your manufacturing, reduce errors, and boost productivity.

Contact Us4. PBC Linear uses augmented reality (AR) to improve training in advanced manufacturing. It provides workers with interactive, step-by-step instructions via Taqtile's Manifest platform. This lets PBC Linear turn expert knowledge into digital guides, reducing training time and ensuring consistency in processes.

With AR, new employees can follow visual instructions in their workspace. This makes it easier to learn tasks accurately without needing much oversight.

5. SMA Solar Technology AG boosts customer support with AR apps, including the SMA Remote and SMA Virtual Support apps.

The Future of AR in Manufacturing

The AR in the manufacturing industry is set to grow exponentially. AI, IoT, and 5G will boost AR's impact. It will improve efficiency, safety, and innovation in manufacturing.

AR investments today will give manufacturers a competitive edge, improve efficiency, and drive innovation. AR is shaping the future of industrial production, including both manufacturing and real-world applications.

Conclusion

The implementation of AR in manufacturing is transforming traditional production processes. AR is a game-changer in many sectors. It is helping with everything from manufacturing training to car manufacturing.

AR technology boosts efficiency, cuts costs, and improves worker safety for companies. As technology improves, we can expect more creative AR in manufacturing. These innovations will continue to change the industry.

Are you ready to integrate AR into your manufacturing processes? Join hands with Kompanions to embrace the future now!